Thread Factories

The Ningbo MH thread factory, spanning across a vast expanse of 150,000 square meters and powered by a workforce of over 1000 skilled employees, is fortified with state-of-the-art machinery and a stringent manufacturing management system. This robust infrastructure enables us to produce 3000 tons of sewing thread and 500 tons of embroidery thread per month.

Sewing Thread Factory

MH sewing thread factory is comprehensively outfitted with sophisticated machinery for pre-winding, winding, dyeing, packaging, and post-processing treatment. Additionally, it houses research and development facilities, sampling units, and testing equipment. The factory primarily specializes in the production of spun polyester sewing threads, core-spun sewing threads, 100% cotton sewing thread, polyester filament high-strength sewing threads, and polyester overlock threads. These products are available in a variety of sizes and specifications to cater to a broad spectrum of customer requirements.

Embroidery Thread Factory

MH embroidery thread factory operates distinct production lines for rayon and polyester embroidery threads. These lines encompass processes such as pre-winding, winding, dyeing, re-winding, and packaging, alongside facilities for sampling and testing. We assure our customers of threads that exhibit high tensile strength, minimal joint presence, vibrant coloration, a soft touch and superior color-fastness.

Test Center

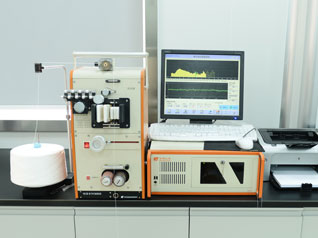

Our test center has a complete set of test equipment, raw material would be tested before using on producing line, and finished sewing thread would be tested for its evenness, hairiness, strength, color fastness and sewing performance, only qualified thread could be shipped out to customers.

Uster Classimat

MQC+Benchtop NMP for Spin Finish

Evenness Tester

Sewing Tester

Color Sample Center

We recognize that providing accurate colors quickly is paramount to our customers’ success and therefore have established an efficient and effective process to deliver with speed. The process starts with expert color teams and advanced color measurement equipment.

Automatic Color Control System

Advanced Infrared Proofer

Automatic Dispensing System

Dyeing and Drying

During dyeing and drying process, we not only care about color matching and color fastness, also we care about dyed yarn spindle shape which will effect thread rewinding quality. As the suitable yarn spindle shape will reduce the breakage rate during rewinding.

Fongs Dyeing Machine

Thies Pressure Dryer

Winding

Our SSM TK2-20CT high-speed precision winding machines, not only ensure the thread cone in good shape with suitable tension, and have no deformation during transportation, but also has excellent performance in length and oil uniformity.

SSM TK2-20CT high-speed precision winding machines

High speed winding machine

Comments