Deciding on the best sewing thread can be tough. This guide simplifies the process by diving directly into the properties of commonly used threads—polyester, cotton, and nylon—and their application in various sewing projects. We’ll also touch on sewing machine compatibility and how to maintain your sewing thread. Whether you’re sewing a delicate silk dress or rugged outdoor gear, you’ll find the information you need to make the right thread choice here.

Key Takeaways

Polyester threads are known for their durability and versatility, suitable for frequent washings and extensive wear, with variations like bonded polyester for heavy-duty tasks.

The selection of sewing thread should be based on fabric type, project requirements, and the rigors the final product will face, ensuring compatibility in terms of strength, elasticity, and resistance to elements.

Thread quality is influenced by factors like tensile strength, abrasion resistance, and refinement processes such as mercerization and bonding, which enhance performance and longevity.

Understanding Thread Types

The first step in selecting the appropriate thread for your sewing project is familiarizing yourself with the various types of threads on the market. Each thread type – polyester, cotton, or nylon – offers unique properties that can either enhance or hinder your project’s outcome. But how do you know which one to use and when? Let us venture into the realm of threads to dissect the facts.

Polyester Threads

Polyester threads are superior in terms of durability and versatility. They are known for their high durability, making them a go-to choice for projects that will face frequent washing and extensive wear. What’s more, polyester threads are known to produce less lint, contributing to your sewing project’s longevity.

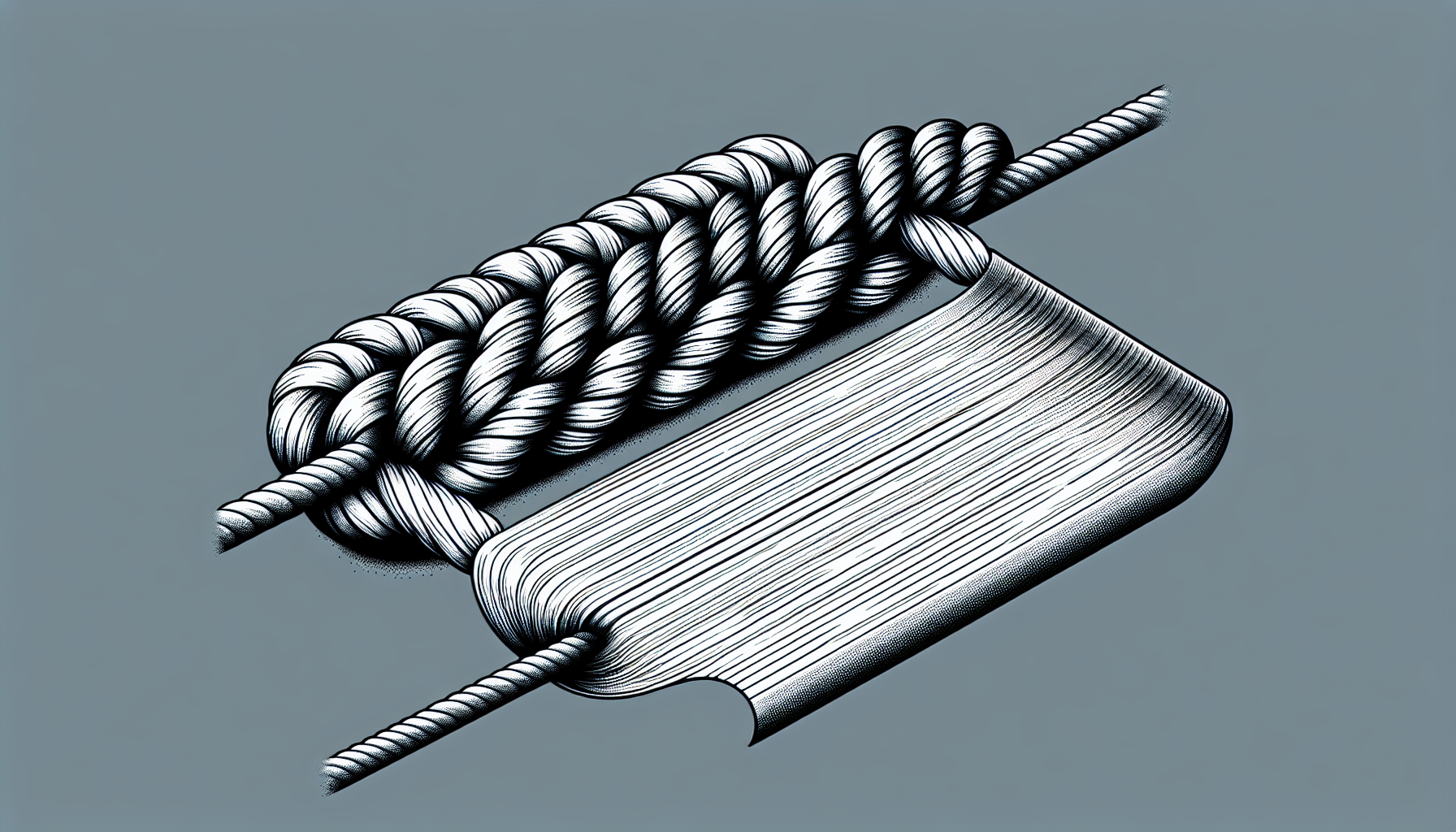

Some polyester threads, like bonded polyester, are even coated with a soluble resin to enhance their resilience, making them ideal for heavy-duty tasks with filters applied. Polyester fibers, in this case, contribute to the strength and durability of the threads.

Cotton Threads

Cotton threads, which are made from cotton fabric, offer a natural and breathable feel, making them perfect for comfortable garments. However, they do have their downsides. Cotton threads can shrink, are less resistant to abrasion compared to their synthetic counterparts, and might even mildew.

Therefore, it’s important to take into account the final use of the fabric before finalizing your thread choice.

Nylon Threads

If you’re dealing with stretch fabrics or heavy-duty sewing tasks, nylon threads might be your best bet. Known for their strength and elasticity, nylon threads are excellent for accommodating the flexibility and movement of stretch fabrics. Their inherent strength also makes them suitable for heavy-duty tasks such as upholstery applications.

Besides, their amalgamation of durability and elasticity renders them a flexible option for numerous projects.

Selecting the Right Thread for Your Sewing Project

Having examined the primary types of threads, we can now proceed to discuss the selection of the appropriate thread for your sewing project. The key lies in matching the thread to your fabric, considering the project’s specific requirements, and shopping by project type.

Matching Thread to Fabric

The golden rule of sewing, including hand sewing, is to choose a thread that matches the weight and fiber content of the fabric. When sewing garments, cotton thread pairs well with cotton and linen fabrics due to their similar shrinkage rates, ensuring your seams do not pucker after washing.

On the other hand, polyester thread is versatile and suitable for all types of fabric, as it doesn’t shrink or fade and produces minimal lint, which is beneficial for machine cleanliness.

Considering Project Requirements

Before selecting a thread, consider the specific requirements of your project. For instance, if you’re working on industrial items like tents or footwear, a thread like bonded nylon that is resistant to temperature and wear would be an ideal choice. Similarly, if you’re designing activewear, you’d want a thread that has the right balance of strength and stretch.

Also, remember to choose threads resistant to chemical damage if the sewn items will undergo harsh treatments like bleaching or dry-cleaning. Lastly, ensure that the thread weight matches the fabric’s to prevent puckered seams and fabric distortion.

Shopping by Project Type

Lastly, shopping for threads based on the type of project can simplify the selection process. For instance, cotton thread is usually preferred for quilting projects due to its lower stretch, which helps maintain the quilt’s structure.

For upholstery work, threads that can handle high stress, like nylon or polyester threads, are recommended due to their superior tensile strength and resistance to abrasion.

And for projects that’ll be subjected to challenging conditions, polyester thread is the preferred choice for its resistance to:

sunlight exposure

contact with mildew

bleaching agents

acids

alkalis.

Thread Quality and Performance

Having discussed how to choose the correct thread, we will now shift our focus to the significance of quality thread and performance. This involves understanding the tensile strength, abrasion resistance, and surface smoothness of the thread you choose, as well as the process of thread refine.

Spun Polyester vs. Continuous Filament Polyester

When it comes to polyester threads, the two main types are spun polyester and continuous filament polyester. Continuous filament polyester threads are made from long continuous strands, offering greater strength compared to spun polyester. This makes them ideal for sewing applications where seam strength is paramount, such as in footwear and leather goods.

On the other hand, spun polyester threads are made of high tenacity staple fibers and are widely utilized in various sewing applications due to their versatility.

Thread Refinement Processes

Thread refinement processes like mercerization, gassing, and bonding can significantly improve thread quality. Here are some examples of these processes:

Mercerization: a chemical treatment that causes cotton fibers to swell, increasing their luster, strength, and dye affinity while reducing shrinkage.

Gassing: thread is passed through a flame at high speed to singe away excess fibers, enhancing the thread’s sheen.

Bonding: bonding agents like polyurethane are often applied to continuous filament polyester threads to bond the plies together, improving overall thread performance.

Testing Thread Quality

Testing thread quality is a crucial part of ensuring your sewing project’s success. One way to test thread quality is by examining the thread for the presence of fuzz, which is an indicator of short fiber use and lower quality. You can also evaluate a thread’s quality by checking for unevenness and imperfections, which can affect consistent sewing performance and seam quality.

Sewing Machine Compatibility

The sewing machine you use is equally as important to your project as the thread you opt for. It’s essential to select a thread that’s not too thick to fit through the eye of the sewing machine needle to avoid sewing issues. Also, consider the type of spool that matches your machine’s spool holder and ensure the thread has a smooth surface finish for better passage through the sewing machine guides.

Lastly, match the thread weight for the top and bottom threads to ensure consistent sewing and prevent issues.

Thread Storage and Maintenance

After selecting the optimal thread for your project, proper storage and maintenance become paramount. Here are some tips to follow:

Keep threads in a cool, dry environment, away from direct sunlight.

Protect threads from dust and moisture.

Store threads free from tension, not wrapped too tightly.

Keep threads away from sharp objects to prevent stretching, deforming, or damaging the thread.

Following these tips will help ensure that your threads stay in good condition for your projects.

Regular cleaning of the storage area and using thread nets on spools can also help maintain thread tension and prevent unwinding or tangling. Lastly, periodically inspect threads for signs of deterioration, such as brittleness or color fading.

Top Brands and Where to Shop

Given the plethora of thread brands in the market, picking the most suitable one can appear daunting. Here are some notable brands to consider:

Coats & Clark: Known for their extensive color range and quality threads, perfect for various sewing needs including heavy-duty projects like denim and upholstery.

Gütermann: Another brand known for their extensive color range and quality threads, suitable for a wide range of sewing projects.

New brothread: Offers high-quality polyester sewing thread kits.

LEONIS: Also offers high-quality polyester sewing thread kits.

For shoppers seeking quality threads for machine quilting, retail stores like JOANN offer a range of top sewing thread brands, such as Coats & Clark, Gütermann, Singer, and Sulky, as well as serger thread options for various sewing projects.

Creative Uses for Sewing Threads

If you believed that threads were exclusively for sewing, it’s time to reconsider! Threads offer versatile uses in crafting that go beyond traditional sewing. Here are some examples:

Creating discreet stitches in quilting

Crafting with invisible nylon threads

Transforming threads into a new fabric-like material that can be sculpted into bowls or used as unique patches

The possibilities are endless.

Donated scrap threads can also be used for children’s crafts and preschool activities, allowing for creativity without the need for new materials. Lastly, threads can be incorporated into wet felting techniques to add a myriad of textures and colors, enhancing the tactile and visual diversity of the fabric.

Summary

The journey to a successful sewing project starts with choosing the right thread. From understanding the properties of different threads to matching thread to fabric, considering project requirements, ensuring machine compatibility, and learning proper thread storage and maintenance, we’ve covered an extensive guide to help you select the best thread for your project. Remember, every stitch matters, and the thread you choose can make all the difference.

Frequently Asked Questions

What thread is best for sewing?

Polyester thread is generally very strong, but if you need even greater strength, consider using polyester buttonhole thread or nylon/poly upholstery thread. Silk thread is also strong and offers a natural fiber option.

What is sewing thread called?

The sewing thread is called filament thread, monofilament thread, or bonded thread, each with its own unique characteristics. Choose the type that best suits your sewing needs.

Is all sewing thread the same?

No, all sewing thread is not the same. There are various types of thread for different sewing projects, including embroidery, quilting, and machine sewing. It's important to choose the right thread based on the specific requirements of your project.

How do I know what thread to use for sewing?

Match the type of thread to the fabric type, such as using polyester thread for synthetic fabrics and cotton thread for natural fibers. Always consider the thread weight and purpose of the project when selecting a thread.

What is the strongest type of thread?

The strongest type of thread is continuous filament polyester, which is ideal for heavy-duty tasks.

Comments